Microfluidics

Lab-on-a-Chip: Downscaling of analytical devices

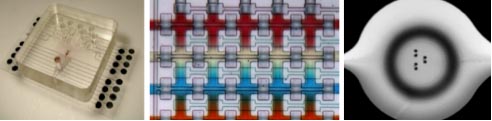

Miniaturization of devices is an important theme in many fields of daily life. An impressing example is the reduction of computer size in the latest decades with a simultaneous increase in performance and efficiency. Thanks to the fast progress certainly pushed by the requirements of the electronics industry, man-made miniaturized structures are available in micro- and nanometer dimensions - these dimensions are comparable to the size of biological cells and macromolecules. For biological and chemical applications, there is a great interest in micro-/nanostructured channel systems and micro-/nanopatterned surfaces. So-called microfluidic devices offer great prospects for carrying out biochemical reactions as well as successive separation and analysis of the reaction products on one chip (µTAS, micro total analysis system).

In general, the miniaturization of chemical reaction systems yields a multitude of advantages over macroscale systems:

- Decrease of sample consumption

- Use as portable stand-alone device

- One-way use, e.g. in medical applications

- Fast heat and mass transfer (increased efficiency in many applications)

- Parallelization, automated process steps

- Modular design: Integration of functional units, e.g. downstream, integration on a microfluidic platform

- The miniaturized devices support handling of small liquid volumes as well as of small objects such as microdroplets or cells

- Natural situations can be mimicked with microfluidic devices, e.g. blood vessels

For the fabrication of the microfluidic devices, we use optical lithography and (multilayer) soft lithography. For detection, we employ optical microscopy and fluorescence spectroscopy. See our infrastructure in the lab tour.