Lab tour

Lab Impressions

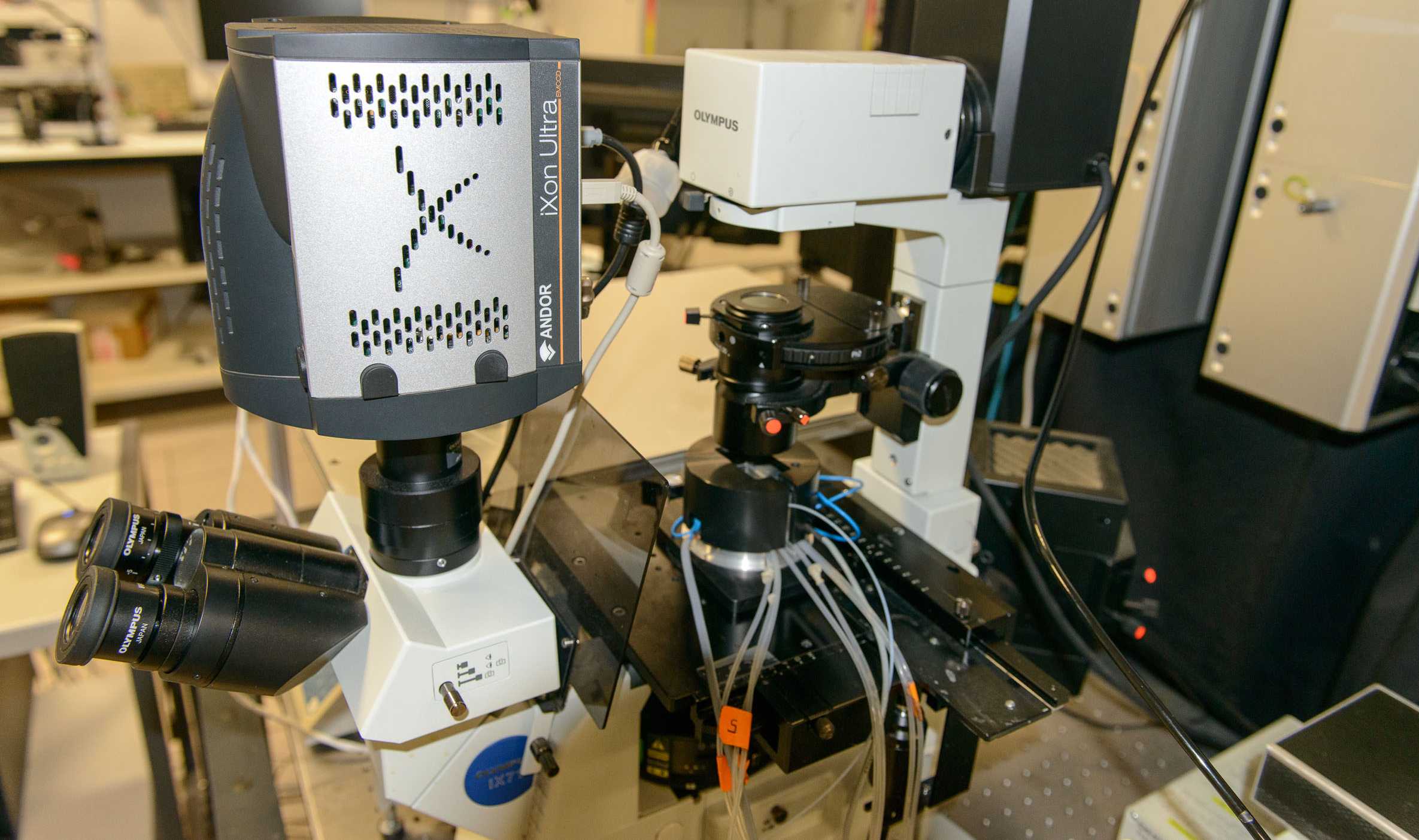

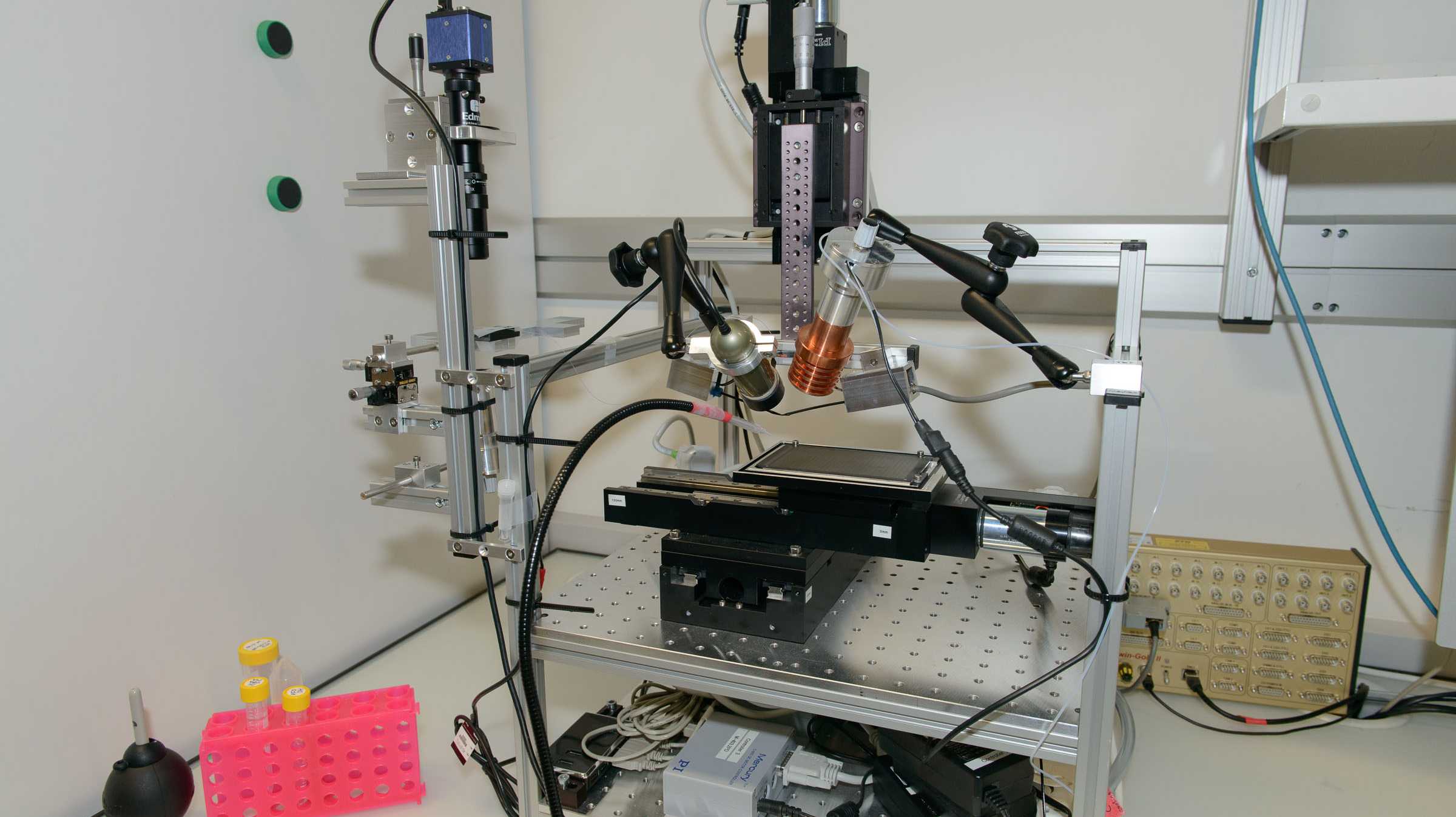

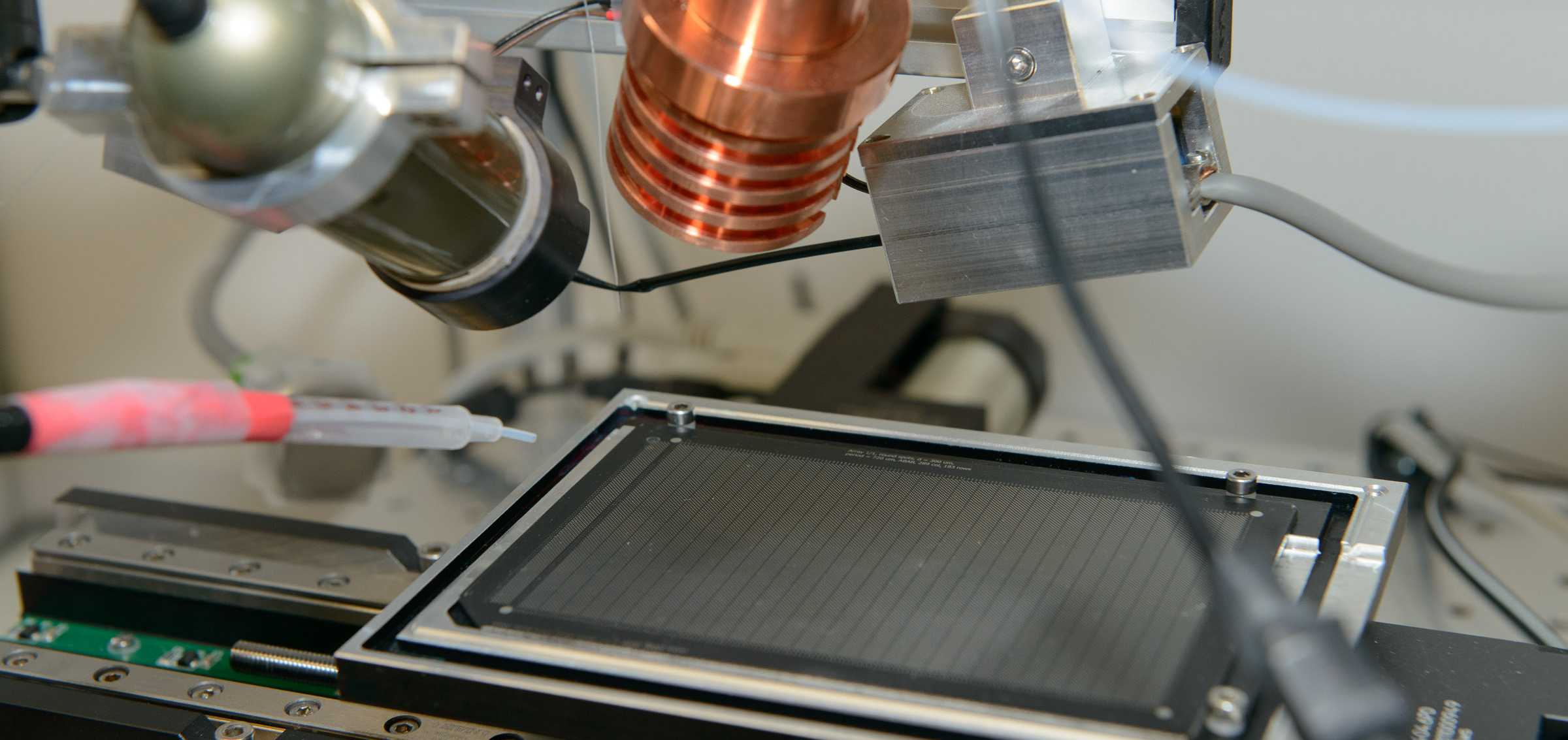

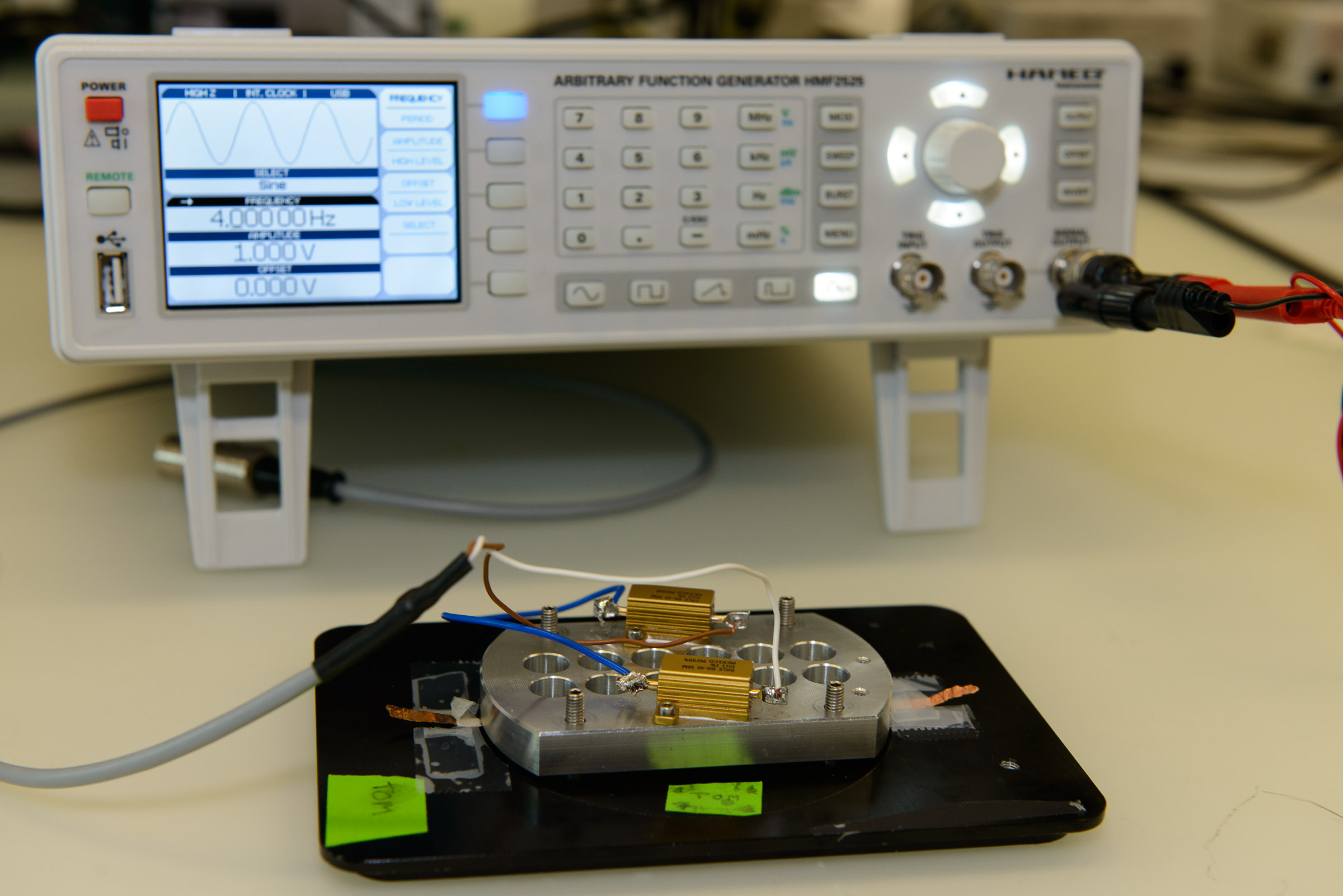

Our studies combine microsystems technology, (cell) biological or chemical assays, and microscopy. See below photographs of the instruments and infrastructure available in the laboratory.

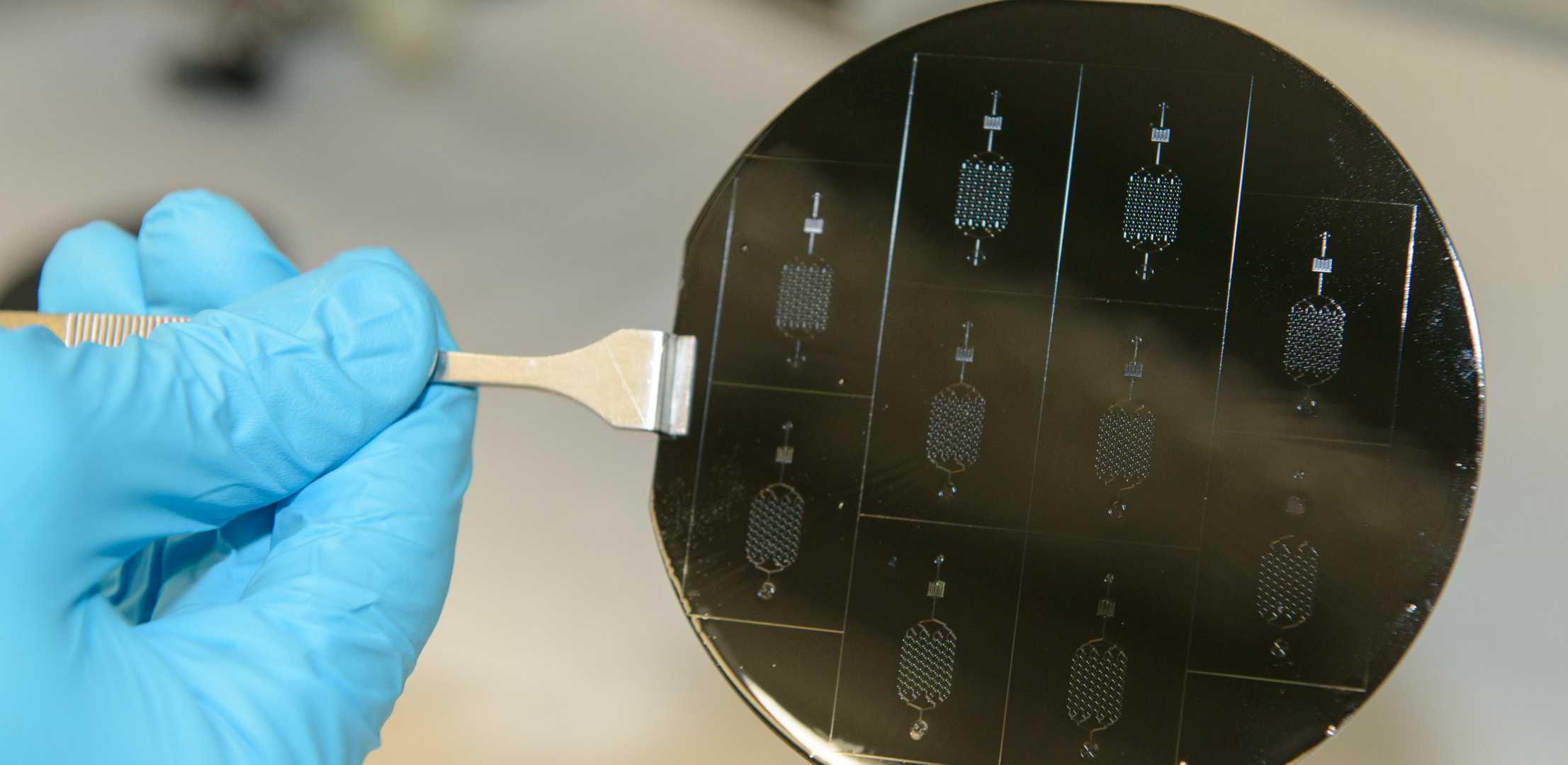

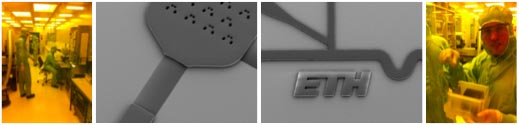

Several materials are employed for chip fabrication. For preparation of polymer chips made of poly(dimethylsiloxane, PDMS), we use a two-step process. First, master forms are prepared by optical lithography done in the FIRST clean room facility. Second, the final chips are made in PDMS by casting, a process referred to as soft lithography. Valves and pumps are integrated, when two layers are used: a fluid and a control layer. Electrodes can be integrated on a glass support.